RF GaN Substrate wafers for GaN-on-Si applications

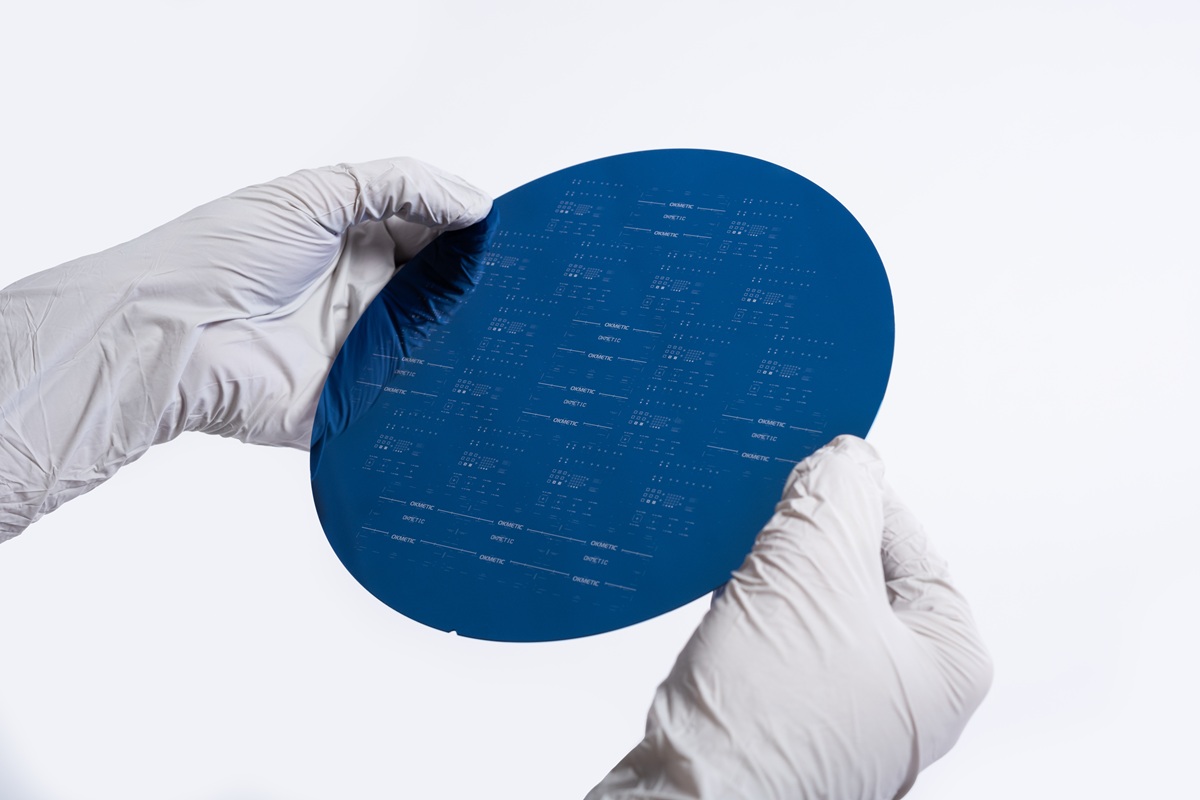

Okmetic RF GaN Substrate wafers are customized high resistivity silicon wafers designed to facilitate the growing of high-quality gallium nitride (GaN) and to drive the insertion losses lower.

Okmetic RF GaN Substrate wafers for GaN-on-Si applications are customized solutions designed to endure the extreme stresses of the gallium nitride (GaN) epi process and to drive the insertion losses lower. Our RF GaN Substrate wafers combine up to ≥ 7,000 Ohm-cm resistivity with optimized Oi level and other wafer parameters decreasing wafer bow and warpage. This combination provides an optimal balance between resistivity stability, lattice integrity and durability.

Silicon wafers designed to endure the extreme stresses of the RF GaN epi process and to drive the insertion losses lower

Okmetic RF GaN Substrate wafers are a result of long-term silicon parameter optimization carried out in close co-operation with several industrial players, utilizing all the widely used GaN production processes. Okmetic also supplies medium and low resistivity wafers for GaN-on-Si applications used in more traditional power devices.

Durable wafers with superior performance

Okmetic RF GaN Substrate wafers are designed to facilitate the growing of high-quality gallium nitride and to offset the extreme stresses of the RF GaN epi process. The high resistivity bulk properties of these wafers keep the insertion losses low and the complimentary full wafer shape analysis enables the systematic refinement of the deposition control loop when used in conjunction with in-situ wafer monitoring.

Okmetic’s has the widest selection of wafer thicknesses in the market ranging from 380 to 1,150 μm and variety of backside film options, which helps with the stress management of GaN-on-Si RF Power substrates. In mixed metal lattices like GaN epi layers the thicker wafers have shown to offset the extreme stresses better than the thinner ones.

Okmetic RF GaN Substrate wafers are available in 111 orientation, which together with optimized Oi help fight the stresses in customer’s GaN-on-Si process. Thanks to Okmetic’s extensive MEMS background, Okmetic has learnt to control the off-orientation extremely well, which helps customers to achieve accurate and successful GaN epi layer deposition.

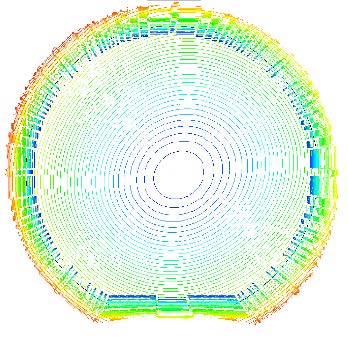

Okmetic silicon wafers have consistently shown superior performance in GaN-on-Si epitaxy. During the GaN epi process, wafer curvature is monitored and controlled. Okmetic wafer bow returns close to the initial stage after GaN stack deposition process. This is illustrated on the left in the geometrical mapping of Okmetic Si substrate processed into a GaN-on-Si wafer at Aalto University of Finland.

RF GaN Substrate wafers have multiple benefits

- Tailored to match the demanding GaN epi needs

- High Resistivity: P-, up to ≥ 7,000 Ohm-cm resistivity with suitable Oi control, balancing between resistivity stability and lattice integrity.

- On-orientation <111> with tight orientation control.

- Custom wafer thickness options to reduce wafer bow and warpage (150- 200 mm up to 1,150 µm).

- LTO option for the back surface for further stress management

- Also Double Side Polished wafers available, if needed.

Specifications of RF GaN Substrate wafers

| Growth method | MCz, A-MCz® |

| Diameter | 200 mm, 150 mm |

| Crystal orientation | <111> |

| N type dopants | Phosphorus |

| P type dopants | Boron |

| Resistivity | Up to >7,000 Ohm-cm*, Available also in Ultra High Resistivity version with >10 kOhm-cm resistivity *Resistivity range varies by dopant and orientation |

| Oxygen | Typically ≤5 ppma or ≤10 ppma (ASTM F121-83). Can be optimized to Customer process. |

| SSP wafer thickness | 200 mm: 550 to 1,150 µm* 150 mm: 400 to 1,150 µm *Other thicknesses possible with certain limitations |

| DSP wafer thickness | 200 mm: 380 to 1,150 µm* 150 mm: 380 to >1,150 µm *Other thicknesses possible with certain limitations |

| Backside treatment | Etched, LTO, Polyback |