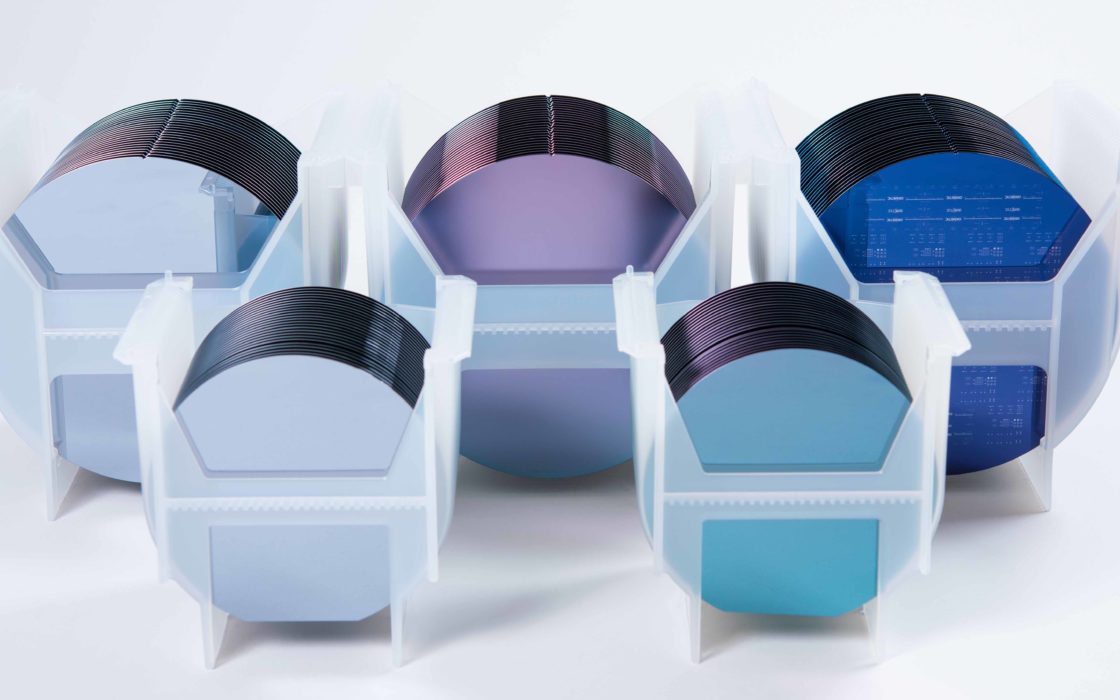

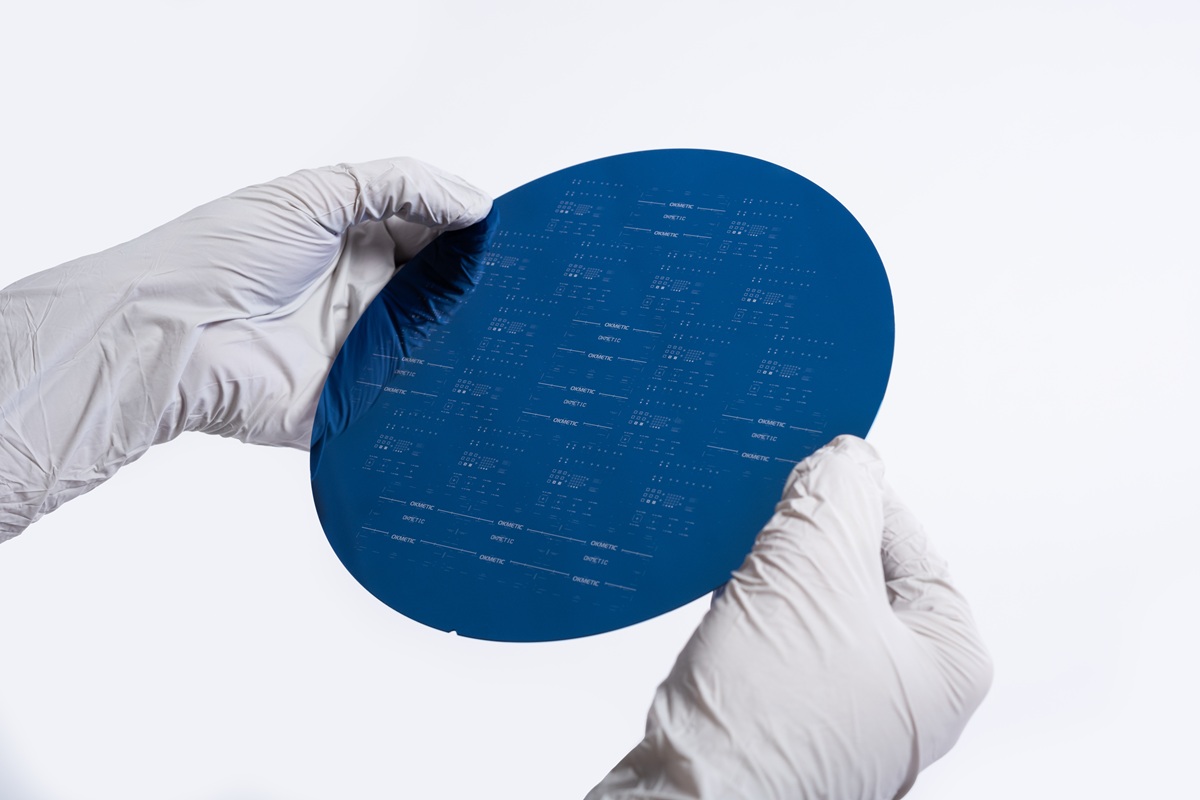

Customized wafers and prototyping

Silicon wafers have a great effect on semiconductor device performance and total cost of ownership. Okmetic’s advanced silicon wafers, customized for your device and process needs enable optimum performance, and our ability for rapid prototyping reduces the time-to-market.

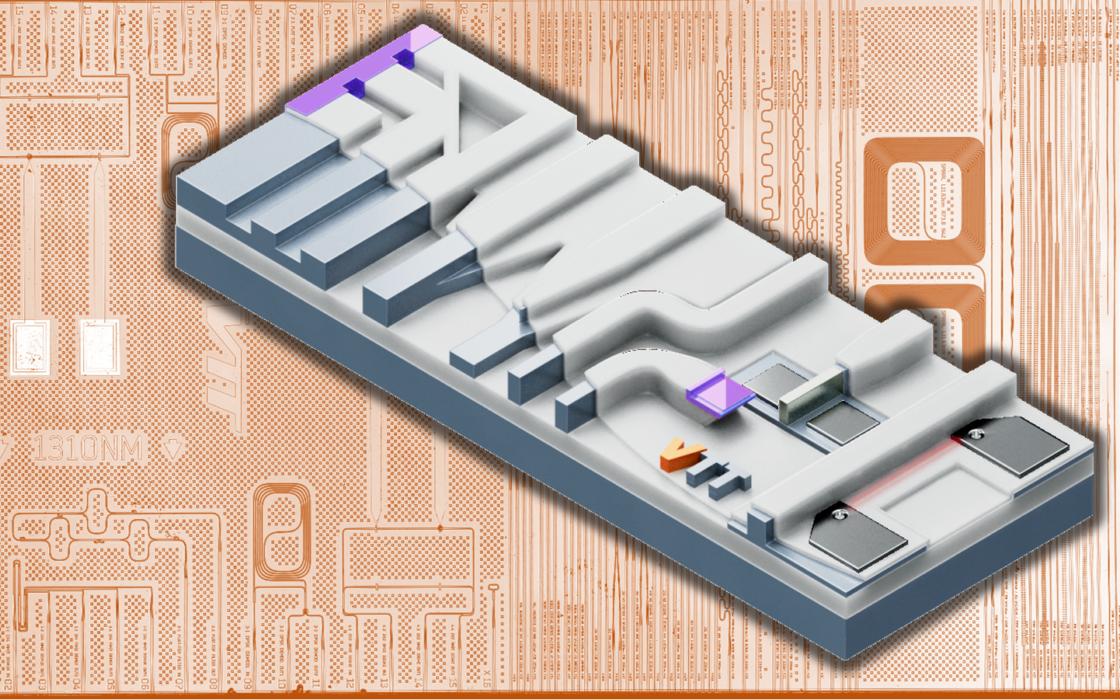

The semiconductor industry is under constant pressure for smaller, higher performance devices and more streamlined manufacturing with lower costs and shorter cycle times. Silicon wafers have a great effect on device performance and TCO. This is why demand for more and more advanced, device and process-optimized wafers and turn-key solutions is surging, and why the importance of rapid prototyping is increasing.

Having a partner who understands your needs and can customize your wafers through agile R&D is essential for improving device performance and reducing time-to-market.

Having a partner who understands your needs and can customize your wafers through agile R&D is essential for improving device performance and reducing time-to-market. Okmetic’s agile wafer design and optimization in R&D, as well as responsiveness and support for smaller order quantities, provides you a talent resource to compliment and complete your in-house expertise. When developing a new device or application, it is ideal to engage your partner as early as possible to ensure a highly optimized and process-tailored wafer solution.

With over three decades of crystal growth and wafer expertise, Okmetic is a proven, reliable partner who understands the unique material parameters in your products. Our Sales, Customer Support Engineers, and R&D Scientists work in seamless co-operation with you to understand your challenges, offer potential solutions, and secure the best solution.

Customization ensures optimum wafer performance

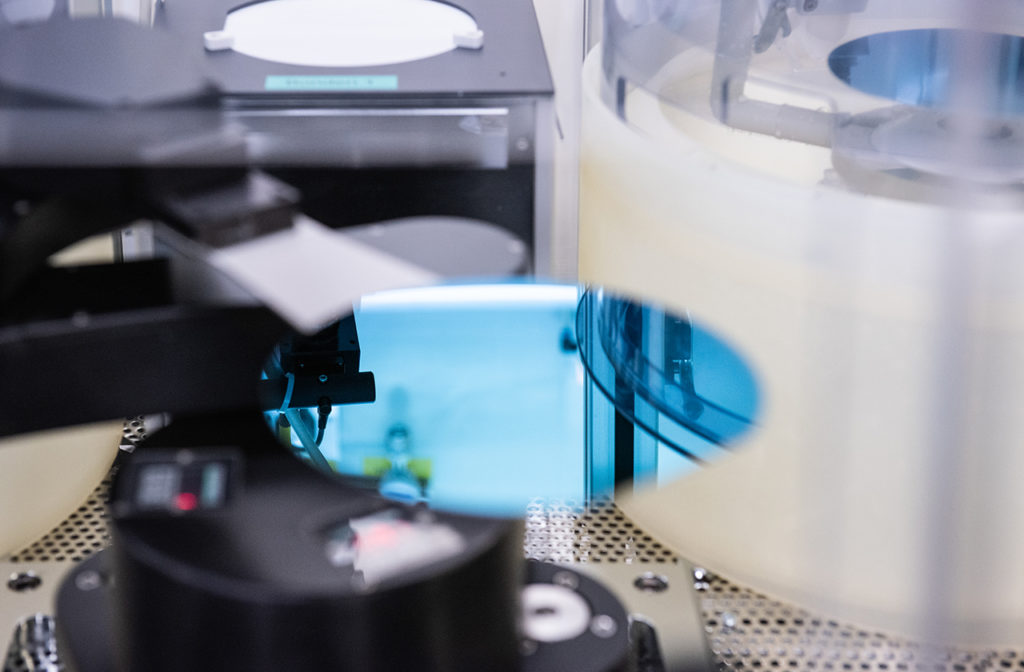

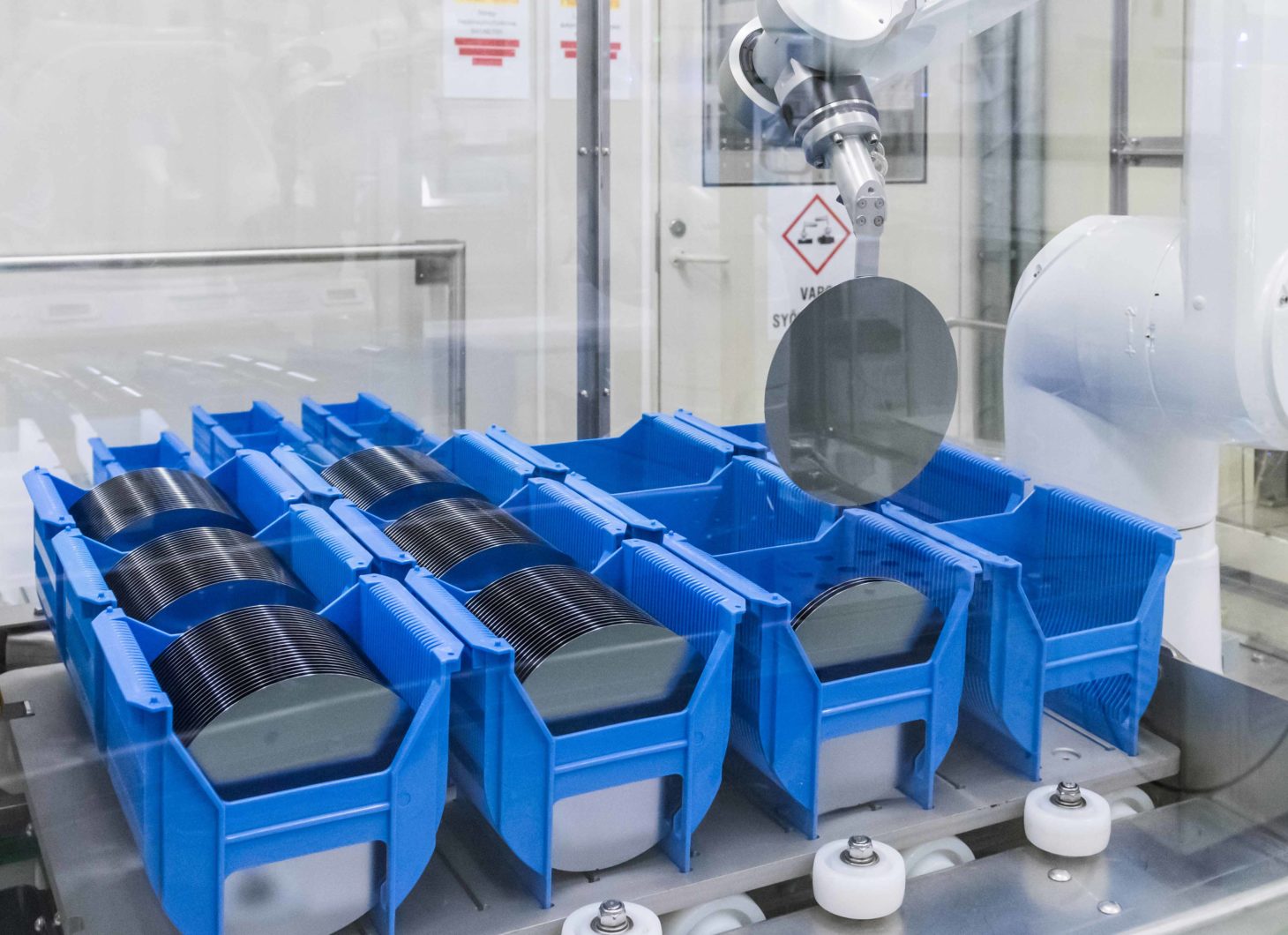

Okmetic’s business model focuses on bringing true value for the customer through customized, high-quality silicon wafers and exceptional service and deep understanding of customer needs. Each batch of Okmetic’s silicon wafers is tailored to the customer’s product, process and technology needs, and produced in volume production. The customization process begins from crystal growing during which many of the wafer parameters are being defined and which is at the very core of Okmetic’s expertise. Customer specific tailoring ensures optimum wafer performance leading to multiple customer benefits: increased device performance and functionality, more advanced design possibilities, improved yield as well as streamlined and cost-effective manufacturing.

Our high quality production is flexible and efficient. We develop our products and processes continuously.