5S at Okmetic

Okmetic has for years made efforts to promote the principles of 5S in the operations of the entire organization: Seiri, Seiton, Seiso, Seiketsu, Shitsuken; or in English: Sort, Set in order, Shine, Standardize, Sustain.

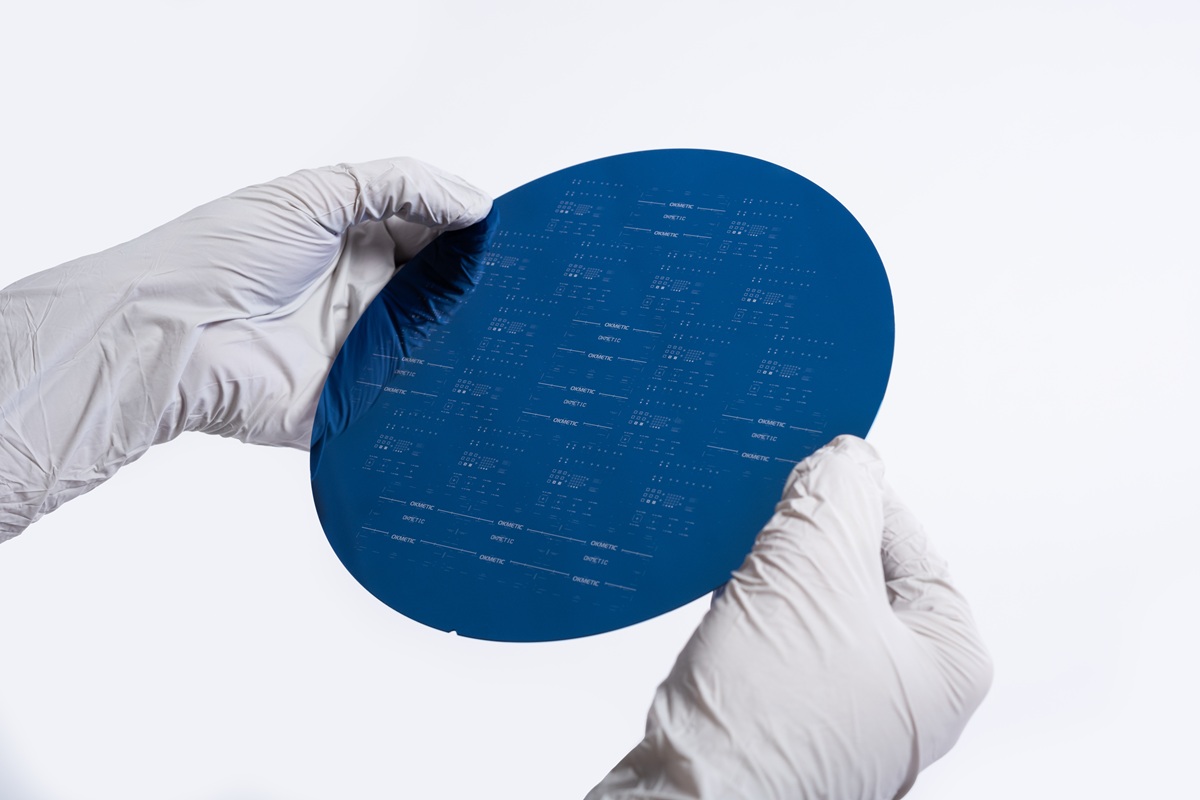

The quality of our products and operations is a central competitive factor. However, quality does not solely involve technology, machinery and processes, as human factors also have a significant impact on the quality of products and work. For this reason, we have selected 5S as a key principle in order to systemize standardized work and prevent errors.

5S is above all a method to reduce the number of human errors and improve the company’s efficiency. It helps us promote safe and high-quality work.

5S does not only apply to the production, but the entire supply chain. It enables an efficient, productive, high-quality and safe working environment and removes wastage of operations.

We aim for an extremely clean and systematic work place where deviations and bad practices are easily recognized. Visual management, one of 5S’s drivers, supports working and guides our staff through a variety of phases in the processes.

5S has a significant impact on work satisfaction and work place culture. We aim to reinforce a culture of continuous improvement and learning through staff training. Respecting others, engagement and learning are all our core aspects of 5S.